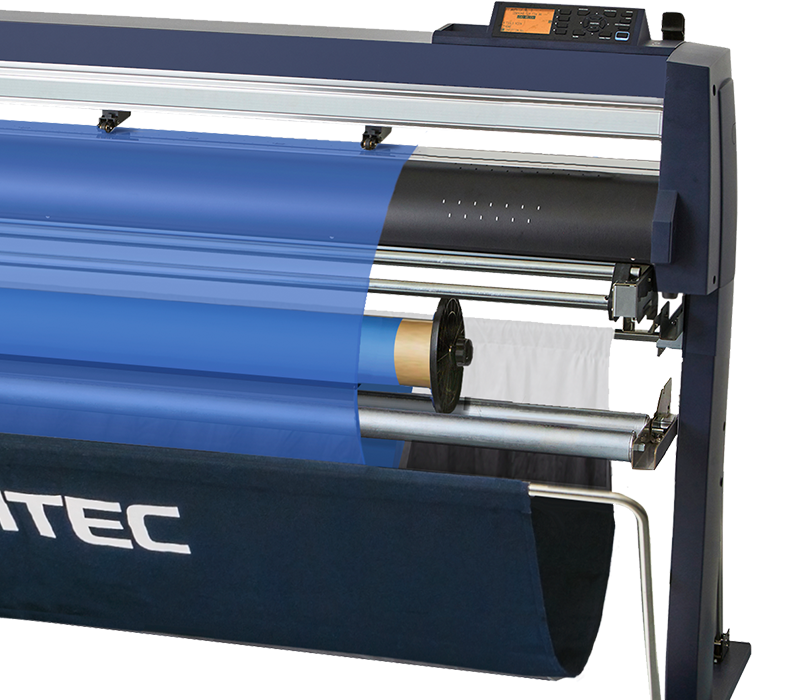

Graphtec FC9000 Series is our most advanced and versatile roll-fed cutting plotter to date.

With its renowned reputation worldwide for dependable, high-precision cutting capabilities on both printed and unprinted materials, the FC Series serves as the ultimate finishing solution for a wide range of industries, including wide-format signage, apparel, and automotive applications.

The FC9000 Series features a newly developed feeding system and cutting head, resulting in even better cutting quality for thin and thick materials, ranging from delicate window tint to high-intensity reflective materials.

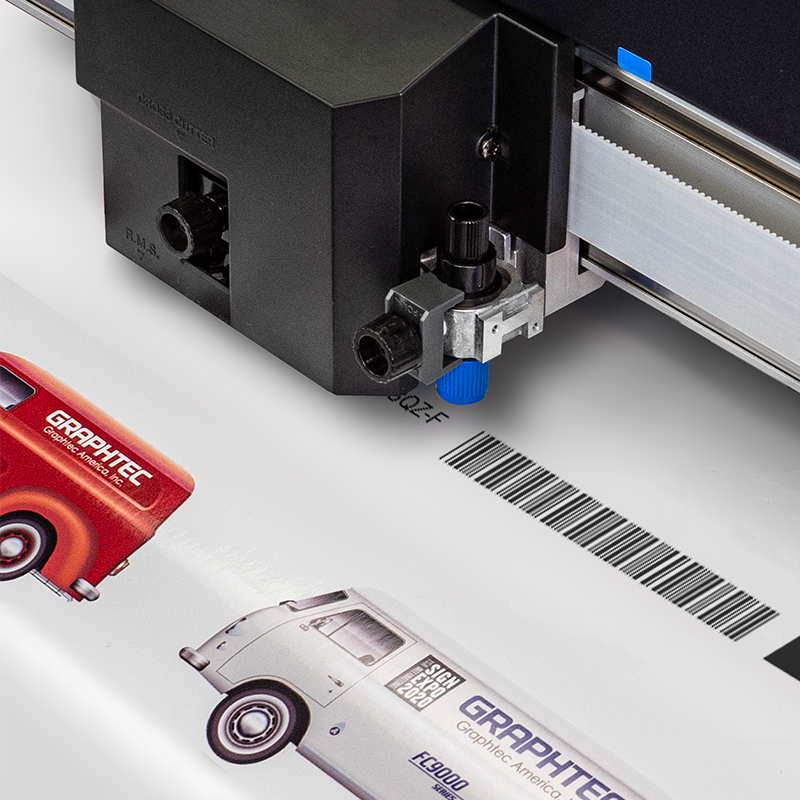

NEW Datalink Barcode System

In addition, ARMS 8.0 introduces Graphtec's Datalink Barcode System, which streamlines job loading and processing automatically, further enhancing the FC Series' efficiency and productivity.

The FC90000 Series comes complete with Graphtec Software

Software includes Cutting Master 5 plug-in for Adobe & Corel Users and our popular Graphtec Studio 2 software for design & cut graphics. The software works with both PC and MAC platforms, or use the handy new USB Thumb Drive Port if needed.

Graphtec makes everything EASY, so contact your Graphtec Authorized Reseller today!

Datalink Barcode

By utilizing barcodes, you can save time and minimize the risk of production errors when handling numerous tasks with just a button press.

DataLink can accommodate any blend of RIP software and printer, along with the bundled software of Cutting Master and Graphtec Pro Studio.

The FC9000 can identify cutting data linked to barcodes from the user's PC or USB flash memory, access the appropriate file, adjust the cutting settings, and initiate the cutting process automatically.

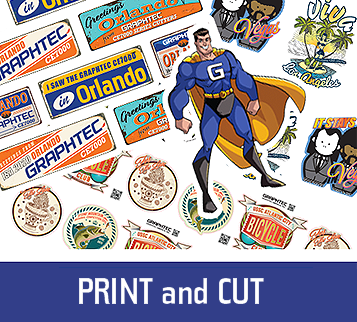

cut accuracy WITH PRINTED MEDIA

Graphtec’s Advanced Registration Mark Sensing (ARMS) technology delivers precise results when cutting printed media in addition to efficiency boosting features.

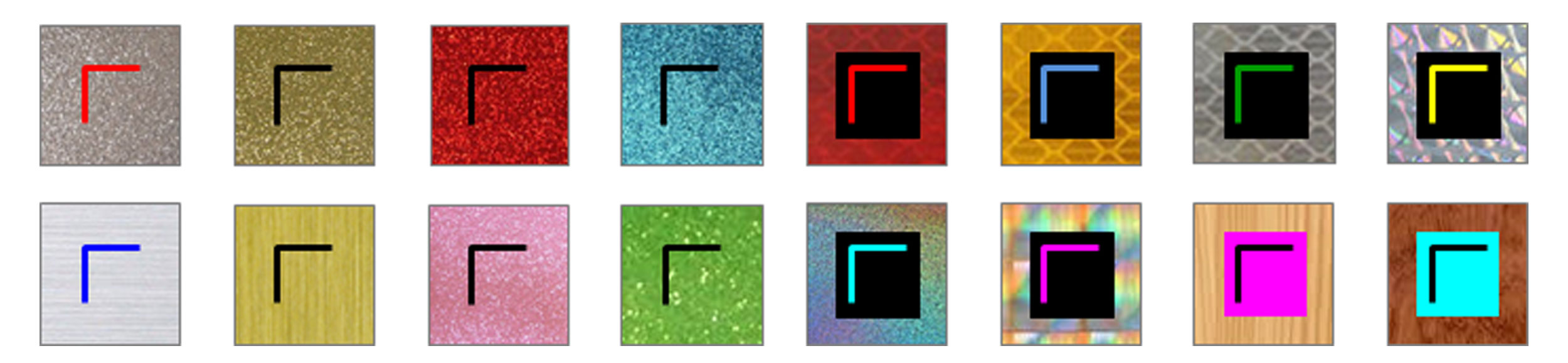

EASILY ACCOMMODATES REFLECTIVE MEDIA

The new white LED sensor and improved search algorithm accurately read registration marks printed from any printer onto a large variety of media types including high gloss, metallic, glitter, and high intensity reflective.

NO FLATBED?

NO PROBLEM!

A re-engineered feeding system has greatly enhanced the cutting capabilities of thin and thick media types.

Add additional push rollers for increased precision when cutting heavy, rigid materials such as magnet, rubber, and diamond-grade high intensity reflective.

Three pressure settings ensure strong media hold-down without leaving track marks.

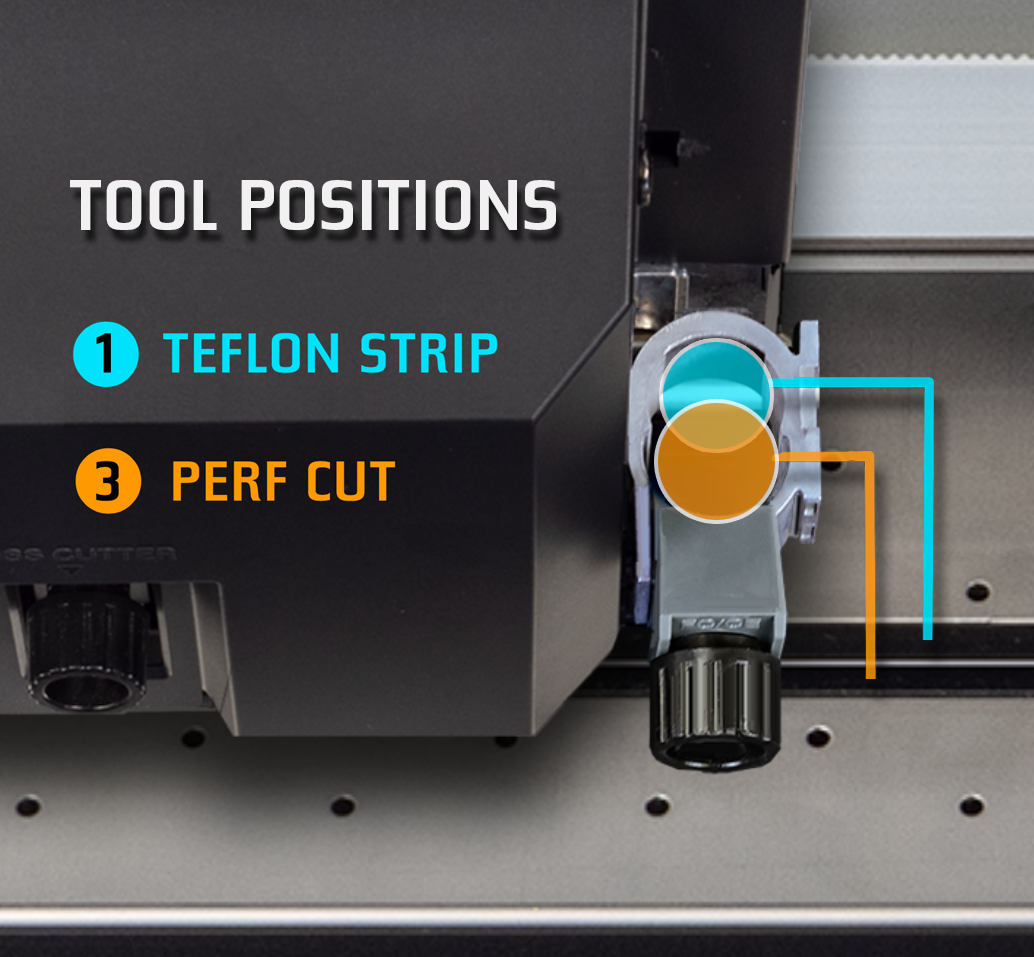

Contour & Die cut with EAse

Separate tool positions for contour and die cutting ensures the longevity of your blades and cutting strip when creating decals and graphics that are effortlessly popped out of sheet and roll media.

Take-up Reel

The Optional Take-up Reel boosts production efficiency by automatically winding rolls of media up to 65 feet long with equipped infrared sensor.

Compatible with the FC9000-140 and FC9000-160.

FEATURES

MARKET Applications

Expand your Capabilities with the Highly Versatile FC9000 Series

STANDARD ACCESSORIES

| Item | Qty | Description |

|---|---|---|

| Cutting Blade | 1 | CB09UB |

| Blade Holder | 1 | PHP33-CB09N-HS |

| Blade Loupe | 1 | PM-CT-001 |

| Stand | 1 | Parts kit |

| Media Flange Set | 1 | OPH-A21 |

| Media Basket | 1 | Parts kit |

| Software Download | 1 | Graphtec Studio 2 & Cutting Master 5 for Mac and PC |

| Manuals | 2 | Setup Manual, Cutting Blade Manual, and Safety Manual |

| USB Cable | 1 | 9.5 feet long |

| Power Cord | 1 | The type of cord is different by destination |

OPTIONAL ACCESSORIES

| Item | Part No. | Description |

|---|---|---|

| Media Flange | OPH-A21 | Flange for media holding |

| Additional Push Roller | OPH-A47 | One additional push roller |

| FC9000-140 Take-up System | OPH-A43 | Automatic Take-up System for the FC9000-140 |

| FC9000-160 Take-up System | OPH-A44 | Automatic Take-up System for the FC9000-160 |

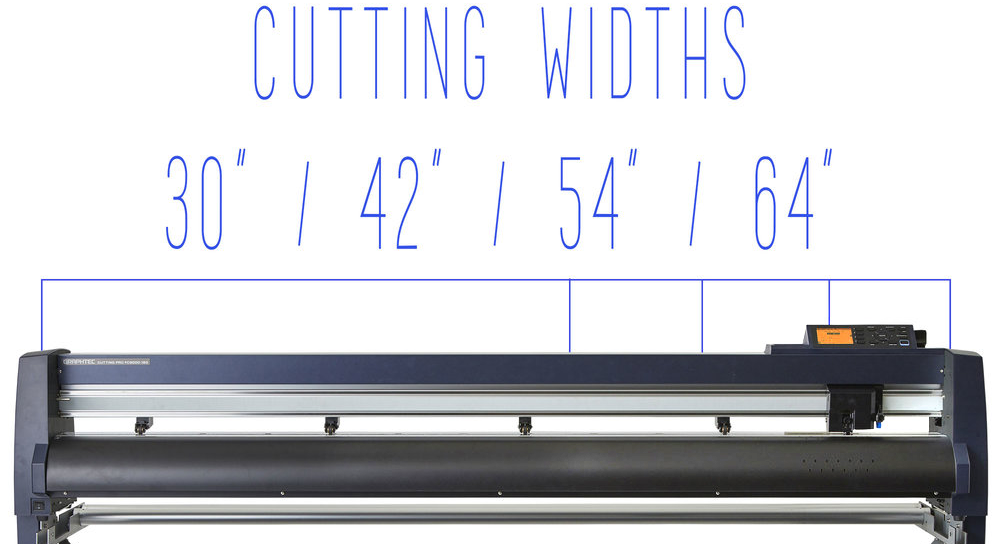

| Model | FC9000-75 | FC9000-100 | FC9000-140 | FC9000-160 |

|---|---|---|---|---|

| Max. cutting area (W x L) (*1) |

30 in x 164 ft 762 mm x 50 m |

42 in x 164 ft 1067 mm x 50 m |

54 in x 164 ft 1372 mm x 50 m |

64 in x 164 ft 1626 mm x 50 m |

| Guaranteed Precision Cutting Area (*1) | 29.21 in x 50 ft | 41 in x 32 ft 35.2 in x 50 ft |

53 in x 32 ft 35.2 in x 50 ft |

63 in x 32 ft 35.2 in x 50 ft |

| Mountable media width(*2) | Min. 1.96 in |

Min. 1.96 in |

Min. 1.96 in |

Min. 1.96 in |

| Max. cross cut width | 30 in | 42 in | 54 in | 64 in |

| Number of push rollers | 2 rollers | 3 rollers | 4 rollers | 4 rollers |

| CPU | 32-bit CPU | |||

| Configuration | Grit rolling plotter | |||

| Drive method | Digital servo drive | |||

| Max. cutting speed | 58.5 inches per second (45 degree direction) 41.3 (axis direction) | |||

| Cutting force | Max. 600 gf in 48 steps | |||

| Axial acceleration | Max. 39.2 m/s2 (4 G) in 8 steps | |||

| Compatible roll media diameter | Min. 2.99 in Max 7.8 in. (Max diameter is 6.29 in when included flange is installed) | |||

| Mechanical resolution | 0.005 mm | |||

| Programmable resolution | GP-GL: 0.1 / 0.05 / 0.025 / 0.01 mm, HP-GL™: 0.025 mm | |||

| Distance accuracy (*2) | Max. 0.1 mm or 0.1 % of plotted length | |||

| Repeatability (*2) | Max. 0.1 mm in plot up to 2 m (excluding the expansion and contraction of the media) | |||

| Minimum character size | Approx. 5 mm alphanumeric (varies depending on character font and media) | |||

| Mountable number of tools | 1 tool (cutting blade, plotting pen or pouncing tool) in standard; 2 tools (cutting blade and plotting pen) when second penholder (optional) is installed |

|||

| Blade types | Supersteel (0.9 mm or 1.5 mm diameter) | |||

| Pen type | Oil-based ballpoint pen | |||

| Pouncing tool type | Steel pin 1.2 mm diameter, required optional pouncing tool (PPA 33-TP12) | |||

| Media types (*3) | Self-adhesive marking film (vinyl, fluorescent, reflective, high-intensity reflective film) up to 0.25 mm thick,Automotive protection and window tinting film, Sandblast resist rubber up to 1 mm thick | |||

| Compatible paper for pouncing | Regular paper from 0.06 to 0.13 mm thick | |||

| Cross-cutter | Built into the tool carriage | |||

| Perforation cutting | Supported (performed by force control) | |||

| Interface | USB 2.0(Full Speed), Ethernet 10BASE-T/100BASE-TX | |||

| Buffer memory | 2 MB | |||

| Command sets | GP-GL / HP-GL™ emulation (Set by menu or command, and selects from GP-GL, HP-GL™, or Auto select) | |||

| Condition settings | Dual configuration (save two (2) user settings with eight (8) separate condition settings per user) | |||

| Display | Graphic type LCD (3.7-inch, backlight) | |||

| Power source | 100 V to 240 V AC, 50 / 60 Hz | |||

| Power consumption | AC100-240 V, 50/60 Hz | |||

| Operating environment | 50 to 95 ºF, 35 to 75 % R.H. (non-condensing) | |||

| Guaranteed accuracy environment | 60 to 89 ºF, 35 to 70 % R.H. (non-condensing) | |||

| External dimensions (W x D x H) |

50" x 28" x 48" 1270 x 711 x 1219 mm |

61.8" x 28" x 48" 1570 x 715 x 1219 mm |

73.6" x 28" x 48" 1870 x 711 x 1219 mm |

84" x 28" x 48" 2133 x 711 x 1219 mm |

| Weight (*8) | 108 lbs. | 123 lbs. | 141 lbs. 178 lbs. /w take-up |

154 lbs. 195 lbs. /w take-up |

| Included Software(*6)) | Graphtec Studio 2, Cutting Master 5 Plug-in for Windows and Mac | |||

| Compatible OS (*5) | Windows 11 /10 / 8.1 / 64-bit editions & MacOS 10.2 (Sierra) to 13 (Ventura) | |||

| Warranty | 3 YEAR WARRANTY | |||

| Safety | PSE, UL/cUL, CE mark) | |||

| EMC | VCCI Class A, FCC Class A, CE mark | |||

*1: Operated with Graphtec specified cutting conditions and media.

*2: There are conditions for operation when setting the media.

*3: HP-GL is a registered trademark of Hewlett-Packard Company.

*4: CB15UA/CB15UA-K30 blades and reinforced backing sheets are recommended for certain grades of high- intensity reflective film.

*5: Graphtec does not support software / drivers used with operating systems that have become obsolete and are no longer supported by the OS developer.

*6: Software is available for download from Graphtec’s website.

*8: Includes stand and basket.

SPECIFICATIONS

BROCHURES

FC9000 Brochure

FC9000 Spec Sheet

FC9000 - Take-Up System

High Intensity Reflective Media

VIDEO TRAINING

Graphtec Video Training is a comprehensive series of instructional videos that are key to fully understanding the versatility of the FC9000 Series Cutters. Advanced Features and Optional Accessories are also demonstrated in depth, so you can be fully trained and ready to boost productivity by mastering all the capabilities of this powerful cutter.

ASSEMBLY AND SETUP

SOFTWARE

CUTTING PRINTED MEDIA

ADVANCED FEATURES