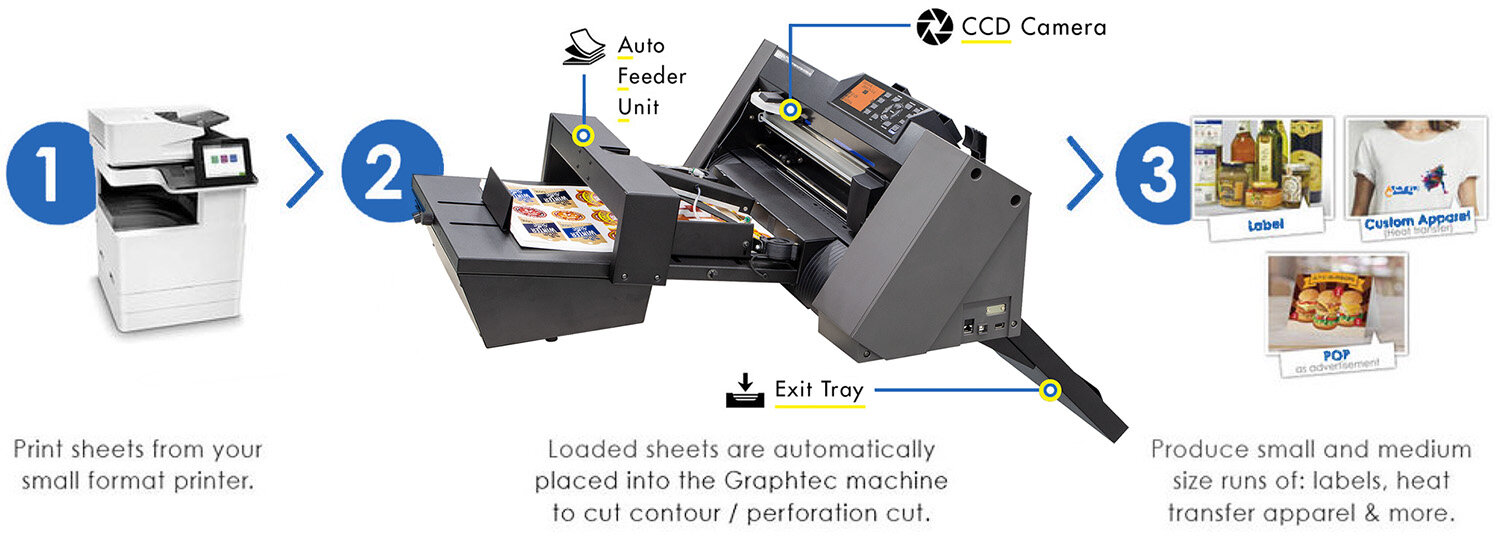

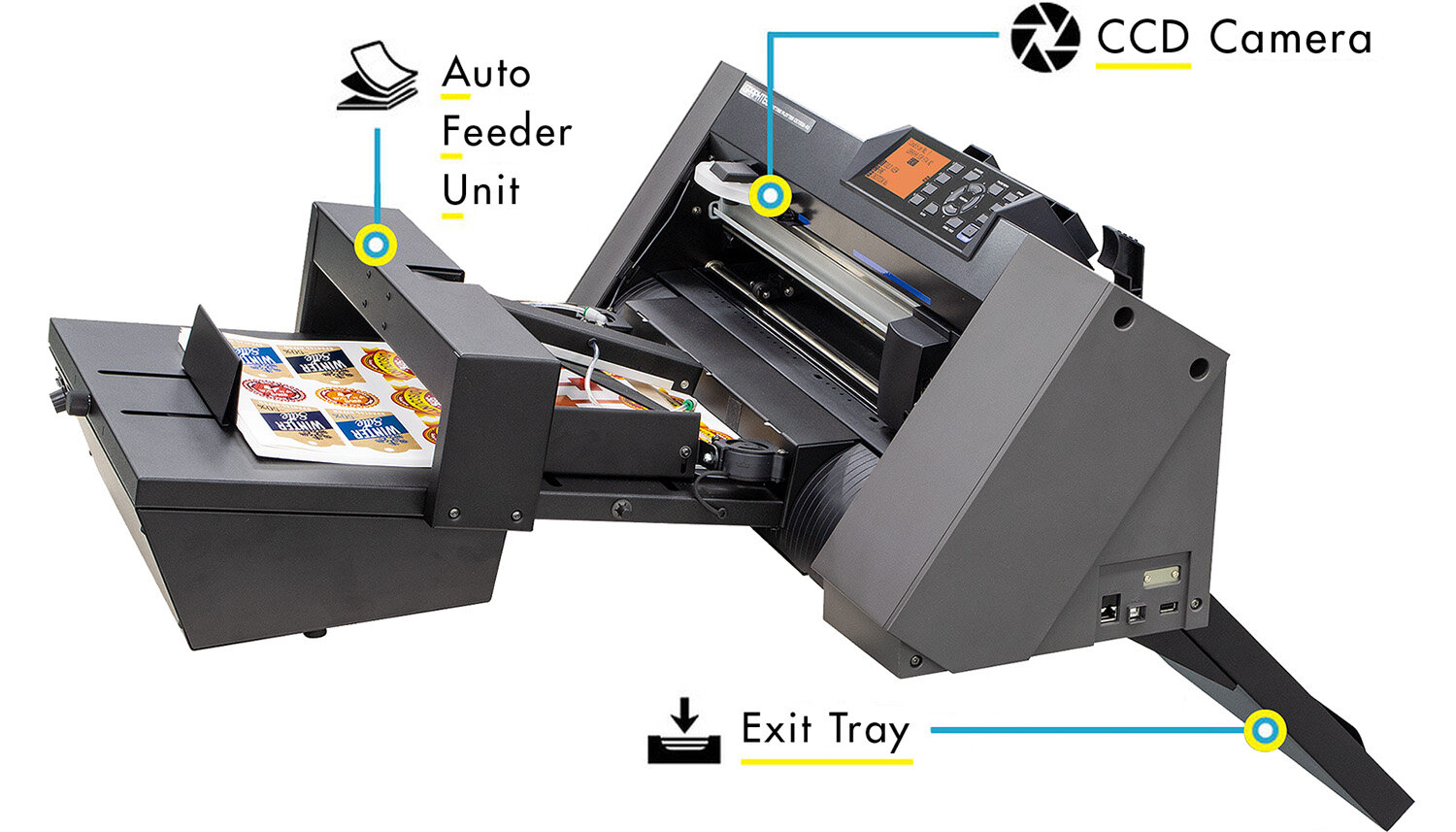

The F-MARK2 Automatic Sheet Feeder, which includes the CE7000-40 cutting plotter, is designed to feed and cut the contour of a design on materials up to 13”x 19” without the need for someone to operate it. An arm with a suction cup system allows you to feed the plotter by lifting the material and placing it inside the plotter. It includes Software and a CCD Camera that allows the material to be precisely aligned to efficiently perform cutting and perforation functions on pre-printed graphics and thus occupy human resources in other tasks. Once the cut is completed, each sheet will fall freely into the Exit Tray. Additional sheets of the same design can be loaded during cutting without re-submitting the job from the computer, thus improving productivity.

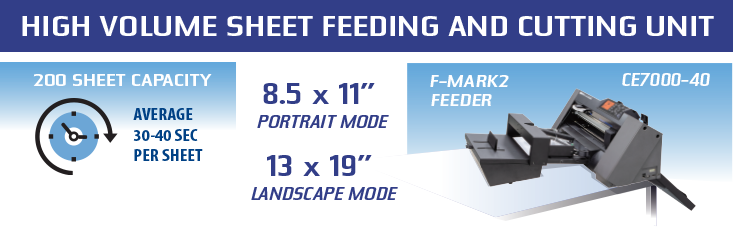

The F-Mark2 can handle up to 200 sheets (depending on thickness) of material in a continuous cycle but with the ability to add more sheets without being required to interrupt the cutting process. This is a feature that will differentiate the F-MARK2 and place it above any sheet feeding system.

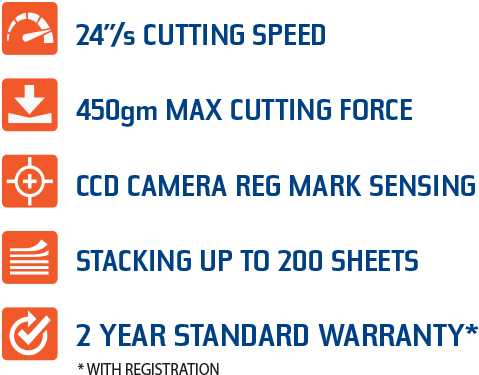

450 grams of cutting force allows the user to carry out small or medium productions of: Labels, business cards, thermal textile transfer and more. Using an EPS file from Adobe Illustrator or Corel Draw, simply add registration marks to your design and import into iMark Plus software for faster, higher-quality results.

CUT LABELS Quickly and Efficiently with the Graphtec F-MARK2 Automatic Sheet Feeder

• HANDS-FREE Continuous Sheet Feeding and Processing

• Dedicated software to ensure ACCURATE alignment

• CCD CAMERA to quickly scan 2 points of registration marks

• CONTOUR CUTTING AND PERFORATION of printed graphics.

• Add additional sheets to the feeder without resending the job

INCREASE PRODUCTION EFFICIENCY BY AUTOMATICALLY RELOADING MEDIA

The automatic sheet feeder reloads the material into the cutting plotter automatically. The cutting process is executed repeatedly by reloading the material. This allows increased productivity by cutting large amounts of material with the same design. The following steps are repeated continuously automatically until the set number of copies are made.

CCD CAMERA DETECTS

REGISTRATION MARKS

CONTOUR CUTTING

MEDIA TO EXIT TRAY

PERFECT ALIGNMENT OF MEDIA SHEETS

Perfect sheet alignment is achieved by reading registration marks for each sheet with a camera equipped with ASC technology allowing adjustments in the reading of marks in a fraction of seconds. Software which, through algorithms, compensates for any distortion in the printing process to allow precise cutting and reduce waste. It also has an option to make perforated lines during file creation.

HANDS FREE MEDIA FEEDING

APPLICATIONS

It is suitable for the post-production of pre-printed materials created in small and medium productions to develop products such as

Labels, Thermal Transfer for Personalization, POP Advertising, etc.

FEATURES

MAXIMUM MATERIAL SIZE 13”X19”

STACK UP TO 200 SHEETS

30-40 SECONDS AVERAGE PER SHEET

AUTOMATIC SHEET FEEDER

An arm with a suction cup system lifts the material from the feeder and places it on the cutting plotter.

You can place sheets of material from 8.5” x 11” to 13”x19” and their equivalent in the feeder. Up to 200 sheets of material can be stacked or up to 1.4” high (The number of sheets will vary depending on the material, thickness and condition of the material)

EXIT TRAY

After cutting is completed, the media sheets are automatically output to the Exit Tray.

CCD CAMERA

The Camera quickly detects 2 points of registration marks to align the contour and pre-printed images using the camera that is mounted on the top of the cutting plotter.

The contour cut will allow you to make different types of cuts such as half cuts, perforated cuts, intermittent cuts and scoring cuts which mark the material for folding. These will allow you to expand your capabilities and type of products that can be produced.

The position of the contour cut will be adjusted in the specialized software using the registration marks. The ARMS (Advanced Registration Mark System) on the cutting plotter will not be used to align the contour.

• Location of the 2 registration marks (black box) will be located on the left side of the material.

• Match the cutting contour with the pre-printed image even if the image has some distortion.

• Registration Marks are quickly detected by the camera mounted on the cutting plotter.

• The Sensor marks on the CE7000 cutting plotter are not used.

SOFTWARE FOR DIGITAL CUTTING (FOR WINDOWS)

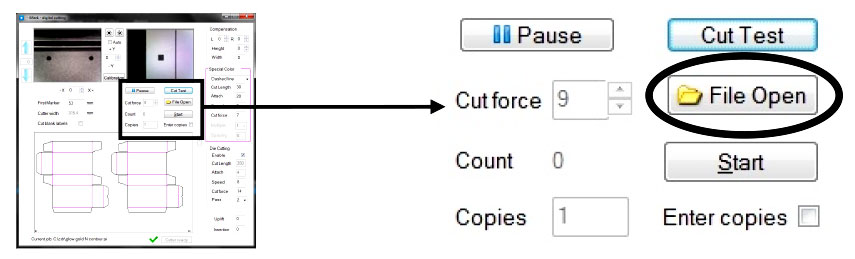

Specialized software controls the feeding system and transfers contour cutting information to the plotter.

The system includes software for specialized applications. After the material is fed, the installed camera quickly detects 2 registration marks and corrects the alignment before contour cutting information is sent giving a perfect cut every time. The software configures cutting conditions such as numbers of copies, cutting force, speed, offset, and number of passes and can import Adobe Illustrator or Corel DRAW cut files.

SOFTWARE

iMark PLUS DEDICATED SOFTWARE CONTROLS THE SHEET FEEDING SYSTEM

AND TRANSFERS CUTTING INFORMATION TO THE PLOTTER

The software controls the feed of material to the plotter and adjusts the position of the contour cut to the pre-printed image using the fixed camera to read the registration marks. You will also configure cutting conditions on the plotter.

CONTOUR CUT FILE

The contour cut file contains only the image and registration marks. It will be saved in a specific format.

Illustrator: Save as an AI or EPS file in IIllustrator 8 CorelDRAW: Export in EPS format

ALIGNMENT AND CONTROL COMPENSATION

The contour cut position will be adjusted in the F-Mark2 software using the registration marks detected by the camera.

The position of the contour can also be adjusted by setting the parameters appropriately and performing distortion compensation.

CUTTING CONDITION CHARACTERISTICS PANEL

F-MARK2 CUTTING FEATURES INCLUDE:

• Cutting Force

• Speed

• Number of Passes

• Number of Copies

• Cutting Method

• Print Distortion Compensation

• Material Feeding Characteristics

NOTE: The cutting method of the 2 lines can be configured. The element that will be configured will depend on the type of cut you want to make. Cutting Master 4, Cutting Master 3 and GRAPHTEC PRO STUDIO are not compatible with F-Mark2

Cutting Conditions when using Special Line Patterns:

The special color line in the imported cutting file can be executed by a specific cutting method different from the normal cutting method of the file, i.e. the material can be processed by 2 different cutting methods if necessary

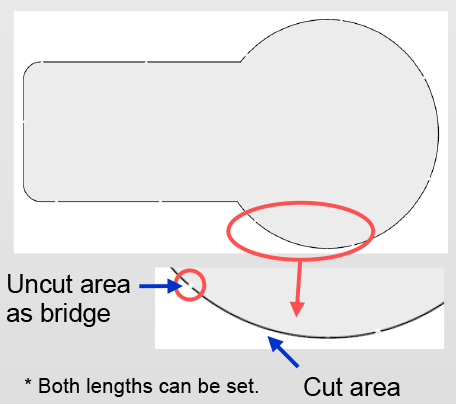

HALF CUT

When the half cut is made, it will be represented by a magenta line, while if a line of another color is used it will represent the perforated cut. These lines will be displayed in the design preview window on the right side of the screen.

The half cut will only cut the material up to the liner (or before going through it), while the perforated cut will cut through the material.

The speed and force may be established to produce elements that contain a perforated cut and a half cut, whether of the same design or different designs.

Magenta Lines indicate intermittent cut lines

INTERMITTENT CUT LINES

Intermittent Cut Lines are very useful for the development of labels, for example, the development of intermittent lines will allow the seal label to be more easily separated from a bottle when it is opened. It is also very useful for POP signage, as the flashing lines can function as a fold line.

Magenta Lines represent the intermittent line, whose length and spacing between lines can be defined.

It is useful since this intermittent line will allow the development of labels that come off more easily and thus allow the opening of some element. These flashing lines will also be displayed in the PREVIEW window on the right side of the screen. When using the perforated cut for packaging development the flashing line will show the position where the design will be folded.

PERFORATED CUT

It is effective for the development of labels, POP signage, paper containers and others. This cut is executed by punching different patterns, figures or designs in the various materials.

With the IMARK PLUS specialized software the material is loaded while the CCD camera quickly detects 2 Registration Marks and corrects the alignment before the contour cut information is transferred, delivering a perfect cut every time.

The software configures cutting conditions such as number of copies, cutting force, speed, offset and number of passes and can import EPS files from Adobe Illustrator or Corel DRAW.

*Designs created in any version of Illustrator or CorelDRAW need to be saved or exported in a specific format.

FOLD MARK EMULATOR

The magenta line is cut by the blade with a special method to emulate a fold line. The cut is made on the back of the material so as not to hurt it. Speed, cutting force, multiple numbers of lines and spacing can be set and modified.

The printed material is set face down in the feeder, starting the process on the reverse side where the registration marks were not printed. The position of the first registration mark is set in the software, and alignment is performed without requiring the camera detects registration marks.

It is useful for creating boxes using line emulation for folding and perforated contour cutting.

IMPORTING CONTOUR CUT INFORMATION

Printed graphics, contour cut lines, and registration marks are designed using any version of Adobe Illustrator or CorelDRAW. The cut line and registration marks need to be saved to the EPS format file in Illustrator 8 or Corel DRAW and then the cut file will be imported into the F-MARK software.

SETTING CUTTING POSITION (NORMAL METHOD)

The imported cut information will result in performing either a deep cut or a half cut. The deep cut will make a cut that will allow the material to be pierced. Cutting conditions such as speed, force and type of cutting line can be configured in the software. The half cut will be useful for making labels or textile thermal transfer. The cutting force can be set above 14

NOTE: Traditional adhesive vinyl labels can be cut with a force between 6 and 9. If more cutting force is required, it is probably time to replace the blade.

The blade should be placed in the rear position of the head.

The half cut is effective for cutting thick paper such as that used in POP materials. The length, spacing and type of line, speed, strength and number of passes can be configured.

The blade should be placed in the front position of the head. The perforated cut will be executed on the cutting plotter.

OS COMPATIBLE

Windows 10, 8.1, 8, 7

SPECIFICATIONS

| UNIT | DESCRIPTION | |

|---|---|---|

| System | Compatible Material Size |

8.5" x 11" |

| Interface to PC | USB port (USB HUB is included to connect the power supply and the cutting plotter) | |

| Energy Source | 100 to 240 V AC (Requires three plugs) | |

| Operation Environment | Temperature: 50 to 95 ºF, Humidity: 35 to 75% RH (non-condensing) |

|

| Size | When the complete system is placed on a table -Size on the table: approx. W 30.4” x D 32.25” x H 12.3” -Size under the table: appox. W 30.4” x D 15” x H 16.5” *The CE7000-40 is placed on the edge of table. Refer to illustration |

|

| Weight | Approx. 55 lb (25 kg) Cutting Unit: 24.25 lb (11 kg), Sheet Feeder: 22,046 lb, (10 kg.) Output Tray: 8,818 lb (4 kg) |

|

| Automatic Sheet Feeder | Compatible Material | Width: 10.63" to 13.78", Length: 8.27" to 19.69" Width: 270 to 350 mm, Length: 210 to 500 mm Up to 450 g/m2 |

| Output Tray Capacity | Up to 200 sheets or 35 mm high (material, thickness and condition vary) | |

| Interface | USB 2.0 | |

| Energy Source | AC adapter, 100 - 240 V AC, approx. 60 VA when connected | |

| Digital Cutting Software |

OS Compatible | Windows 10, 8.1, 8, 7 |

| Compatible format for contour cutting | Ai (saved as Ai 8) and EPS | |

| Cutter Unit | Speed | Max. 600mm/s 24” ips in any direction |

| Acceleration | Max. 69 ft 6.64 in/s2 (21.2 m/s2) (2.2 G) in a 45° direction | |

| Shear Force | Max. 4.41 N (450 gf) with CE7000-40 | |

| Compatibility | UL, cUL, CE mark, RoHS Directive | |

| Energy Source | 100 - 240 V AC | |

| Energy Consumption | Max. 120VA | |

| Warranty | Standard | 2 YEARS |

BROCHURES

TUTORIALS

Graphtec Video Training is a comprehensive series of instructional videos that are key to fully understanding the versatility of the F-Mark2 Auto Sheet Feeder.

Advanced Features and Optional Accessories are also demonstrated in depth, so you can be fully trained and ready to boost productivity by mastering all the capabilities of this powerful cutter.

The Tutorial Section of our website contains all F-MARK2 TRAINING VIDEOS along with instructional videos for our entire line of products. The Graphtec Video Library is also available for viewing on our YouTube Channel.